Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

X-F30 Digital Control Indicator

The X-F30 Digital Control Indicator is a versatile digital control indicator with multiple modes, high stability, bidirectional isolation, and calibration functions for seamless communication.

Product Description of X-F30 Digital Control Indicator

The X-F30 Digital Control Indicator is a digital control indicator that offers multiple working modes, providing flexibility and versatility. With its high stability, it ensures reliable performance. Additionally, it features a bidirectional isolation serial port function, supporting both RS232 and RS485, which facilitates seamless communication with the host system. The calibration functions eliminate the need for weights, simplifying the calibration process.

Product Features of X-F30 Digital Control Indicator

- There are several working modes to choose from, providing flexibility and versatility.

- The device also offers high stability, ensuring reliable performance.

- Additionally, it features a bidirectional isolation serial port function, supporting both RS232 and RS485, which facilitates seamless communication with the host system.

- Furthermore, the calibration functions eliminate the need for weights, simplifying the calibration process.

Product Advantages of X-F30 Digital Control Indicator

- Multiple working modes for flexibility and versatility.

- High stability for reliable performance.

- Bidirectional isolation serial port function, supporting RS232 and RS485, for seamless communication with the host system.

- Calibration functions eliminate the need for weights, simplifying the calibration process.

Technical Parameter of X-F30 Digital Control Indicator

|

Recommended excitation voltage |

220VAC or 24VDC |

Material |

Plastic housing |

|

Accuracy |

0.03%F.S. |

Rated input |

0.5-3.0mV/V |

|

External power supply |

5 VDC |

Resolution |

1/50000 |

|

Non-linearity |

0.03% |

Sampling speed |

15-1920Hz |

|

Hysteresis |

0.03% |

Operating temp range |

-10℃ to 50℃, Humidity ≤ 85% RH |

|

Repeatability |

0.03% |

Display accuracy |

0-50000 |

|

Power Consumption |

about 5W |

Transmit output |

RS232, RS485, RS422, 0-10V, 4-20mA |

|

Alarm Output |

2-way alarm output |

Multi-function switch |

Real-time, peak and valley value |

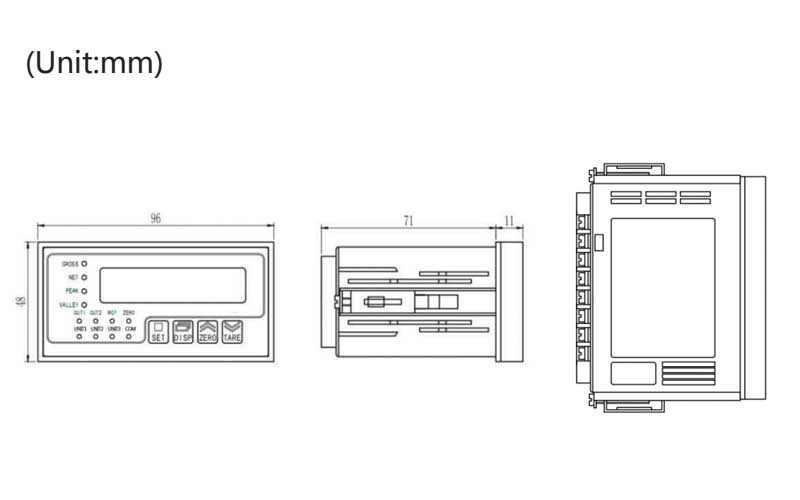

Dimensions

Selection

|

Model |

Input Signal |

Power supply |

Signal output |

Special requirements |

|

X-F30 |

M: mV |

A:220VAC D:24VDC |

R2: RS232, R4: RS485, V:0-10V A:4-20mA |

Y/N |

Product Application

The force measurement device finds extensive applications across various industries, including automobile, medical, robotics, electronics, mechanical equipment, and automation equipment. Its primary purpose is to accurately measure forces in different scenarios, such as stress testing, pull/compression testing, and fit force detection during product assembly. It is commonly utilised in the assembly processes of automobiles, motorcycles, bicycles, electric motors, and motors, among others.